Thermal (Water) Transfer Printing

Have you ever taken a look at your packaging boxes and decided that it just looked too boring, like every other gift boxes of the same make and model out there in the entire world? Then at some point, you must have decided that you want to soup up your packaging box's look a little, give it a flair that is uniquely you and add some personality to it. You might have already checked out all the different surface finish options available to you, adding everything from a new color, new bits and bobs all over your packagings, or even adding motif designs like cool new wooden grains. But what if you want something that looks truly different and amazing?

Film on the intermediate vector graphics using the appropriate pressure transfer to the substrates on the printing method, called the transfer. According to the different pressures used, transfer is divided into: Hot transfer, water transfer, gas transfer, wire transfer, low transfer and so on.

Why Water & Thermal Transfer Printing a great way for packagings?

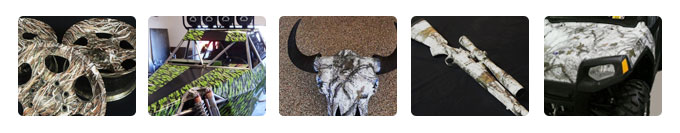

Water & thermal transfer printing is used on everything in packaging industry from jewelry boxes to cosmetics boxes to gift boxes. It is a durable to print on these surfaces a variety of patterns. This method of printing is more durable than paint and decals. It is made to survive in long conditions of direct exposure. Metals, glass, and plastics are the most common boxes to be printed because they are durable materials themselves, wood can warp and splinter so it is only used on hard woods.

The main goal of water & thermal transfer printing is to put a lasting finish, generally a pattern, on a box that will be strenuous wearing conditions.

Cost advantages

Aside from practical uses and branding your packaging boxes as unique it can also add your cost advantages - When you add a unique wood grain to your plastic structured gift or packaging boxes, it helps it stand out with much lower cost than a solid wood box or a MDF box.

Using unique patterns and designs bring another element of safety simply because they draw attention, you don't have to paint your gear safety orange to get attention but something unique and stunning can have the same effect.

Water & thermal transfer printing are new and upcoming technology that has a variety of options and uses ¨C especially the plastic boxes with wood grain will replace solid or MDF wood boxes - It will be exciting to see where this industry goes. It is durable, unique and cost effective, it is going to only grow over the next few years.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Transfer Printing Technology

Known as the more environmentally friendly technology, is currently the newest in a highly efficient print production, probably with his ink from the printing process. Basically, the way water transfer printing works involves taking the specific piece to be printed, pre-treating it, and applying a base coat. The next step is then to put a film printed with the graphic image to be used on top of a vat of water, after which it is dissolved and turned into liquid. Along with this graphic-turned-liquid comes a bonding agent, which will allow it to neatly wrap around the piece that will be printed. Finally, the printer takes the piece, dips it into the liquid for a few seconds, then brings it right back out--and the piece is then flawlessly decorated with no mess and not a single spot missed.

Water transfer printing using water pressure and the active agents so that the water transfer carrier film spin-off of the transfer layer dissolved, the basic process is:

(A) |

Film printing: In the polymer film printed on a variety of different patterns; |

(B) |

The spray paint: A lot of material to be coated with a layer of adhesion agents, such as metal, ceramics, plastic, etc., to transfer a different pattern, you must use a different background, such as the basic use of wood grain brown, brown, khaki, etc. , Stone basic use of white, etc.; |

(C) |

Membrane extension: Let the film flat on the water, and stretch film to be formed; |

(D) |

Activation: With special solvent (activating agent) to enable the transfer film into the ink pattern activated state; |

(E) |

Transfer: The use of water pressure will be through the activation pattern printed on the material being printed on. |

(F) |

Washing: Will be printed on the workpiece residual impurities wash water; |

(G) |

Drying: Drying will be printed on the workpiece, the temperature The Prime of visual material to the melting point may be; |

(H) |

Spray paint: Spray paint on the transparent protective surface protection is printed; |

(I) |

Drying: The spraying paint drying surfaces. |

There are two types of water transfer printing technology, a standard transfer of water technology, the other is coated water transfer technology, the former mainly text and photo images to complete the transfer, the latter tend to the entire product complete transfer surface. Drape transfer technology (Cubic Transfer) using a water easily dissolved in water to carry graphic film.

As the tension of the water coated film excellent, very easy to spiral graphic on the product surface layer, the surface is like painting the same products are completely different look. Drape transfer technology can be coated in any color pattern for the shape of the workpiece, for the three-dimensional product manufacturers to resolve printing problems. Surface coated surface can also add different lines of products, such as striae, wood, jade and other patterns and Marble, at the same time to avoid color printing often is the general board of the virtual spaces. And in the printing process, the products, and printing film surface without contact with the surface to avoid damage to the product and its integrity.

Heat Transfer Technology

In the early days, Heat transfer printing was principally used in the printing of novelty items. Today heat transfer printing has gained significant importance and favor in packaging industries - especially in the packaging & gift boxes sector as an alternative for printing in an agile manufacturing environment.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Transfer Product Applications

-

Plastic boxes, metal boxes, wooden boxes, leather boxes, etc.

-

Point of purchase banners, signage, displays, skirting, carpeting, etc.

-

Advertising specialties - mouse pads, wrist pads, beverage insulators, clip boards, etc.

-

Ceramic tiles, wall murals and interior design

-

Snow skis, snow boards, cycling helmets, in-line skates, water sports equipment

-

Gaming tables , chips

-

Lettering, Rhinestones/crystals

-

Uni-sub wood, clipboards, plaques, signage, vending machines message boards, table tops, counter tops, flooring, etc.

-

Microfiber based sports apparel, T-shirts, caps, swimsuits, jackets, tote bags, cut apparel parts, large format textiles, etc.

The process of transferring images to a large variety of packaging boxes without messy inks by-products or screens is possible with Heat Transfer Technology. The process is fast, it lasts and it is profitable.

(A) |

Heat transfer is to motifs heat-resistant adhesive tape, printing to, through heat, pressure, the ink layer of the tread pattern printed materials to the finished product a technique. Even the multi-colored patterns, due to transfer job is just a process, so customers can reduce the printing pattern operations, to reduce the errors caused by the printing material (finished) losses. The use of thermal transfer printing film can be a multi-color logo into a map, without chromatography, a simple device can also be printed realistic pattern. |

(B) |

Heat transfer equipment used for decorative aluminum-shaped material, all kinds of metal plates can be achieved by wood or marble effect. Dye-sublimation thermal transfer equipment, is based on principles of work, it will be in the 3-5 minutes required for wood or marble grain-shaped material quickly transfer to the aluminum powder-coated surface of the coating can penetrate into the internal 40-60 microns. Aluminum transfer printing production process: First, heat transfer film with the film plane will roll before cutting the size needed. Second, is to cut a good transfer film with the transfer ultrasonic packing machine according to the size of the workpiece into the workpiece using ultrasonic welding package bag. Third, workers will be inserted in the packaging platform, made of the workpiece with the transfer film wrapped bags. Forth is the better package on the thermal transfer printing film machine parts car platform, in turn can put 18 aluminum, aluminum ends will be connected to the vacuum tap and lock, open the vacuum switch, this time tight transfer. Aluminum car automatically sent to the baking furnace, oven temperature 220 degrees and the heat automatically 3 minutes, car voluntarily quit baking furnace. Fifth, release the vacuum tap will remove the workpiece. Sixth is to remove the transfer film, and check the quality of the workpiece. |

(C) |

Offset sublimation production process, first with the film cutting machines will cut to the required size of heat transfer paper rolls. Second, the heat transfer Zhimo attached to the workpiece surface and placed flat heat transfer machine. 3 is pushed to the flat plate heat transfer machine heating zone, pressing the pressure plate switch, thermal transfer paper platen will be tightly pressed on the workpiece, heating and insulation for a minute. Fourth, raising pressure plate will be pushed to the pieces of the workpiece section, remove the transfer film on the workpiece to the next and check. |

(D) |

Thermal transfer technology is widely used in packaging, electrical appliances, daily necessities, building materials and decoration. Because of corrosion resistance, impact resistance, aging, wear, fire, in the 15 years of outdoor use to keep the performance does not change color, etc., almost all goods are produced in this manner with the label. For example, open the phone shell, you can see a packed house with a bar code label. A lot of labeling requirements to withstand the test of time, long-term non-deformation, non-fade, not because of contact with solvents on the wear and tear, not because of high temperature on the deformation of color and so on, so the need to introduce a special kind of material printed media and print materials to ensure that these features, the general Ink-jet, laser printing technologies can not be achieved. |

Heat transfer printing is clean and environmentally safe, which makes it appealing in today's health and safety conscience work environments. There are no suspect liquid by-products. The only by product is paper. Heat Transfer printing is the primary element in apparel manufacturing operations utilizing the increasingly popular agile manufacturing. It is the perfect medium for the demands of today's packaging boxes manufacturing - short run and mass production.

This use in agile manufacturing has been made possible through development and refinement of dye-sublimation printing. With the help of specially formulated dye-sublimation inks and advances in graphics and RIP software packages, operators now have greater control and flexibility which results in a better quality end product. Now short runs of packaging boxes can be printed efficiently, quickly, and cost-effectively in response to real market demand.

Water & Thermal transfer printing are a fascinating process to watch. For one thing, it is so quick and one can hardly believe that it can effectively decorate your packaging boxes in just a handful of seconds. Because it works so well, it is definitely on its way to becoming a popular surface treatment method for packaging industry.

If you are interested in Water & Thermal transfer printing start with UGI ¨C We have a variety of patterns, competitive pricing and a quick turnaround rate. UGI patterns are durable and unique; it makes a great gift or addition to all kinds of equipment.

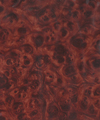

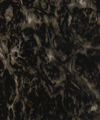

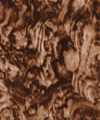

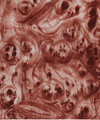

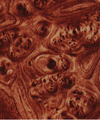

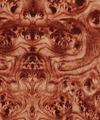

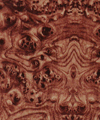

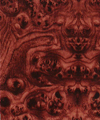

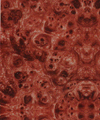

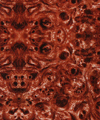

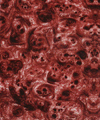

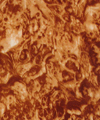

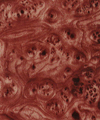

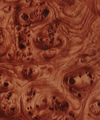

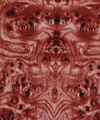

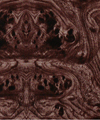

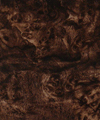

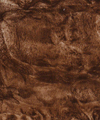

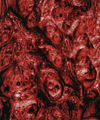

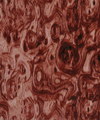

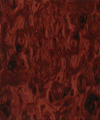

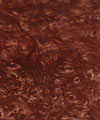

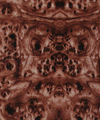

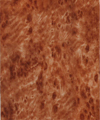

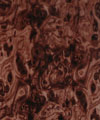

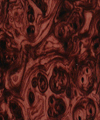

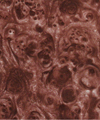

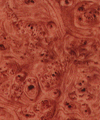

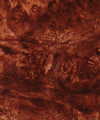

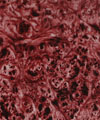

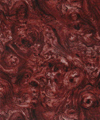

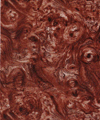

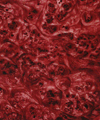

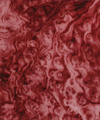

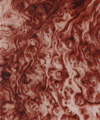

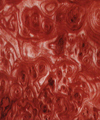

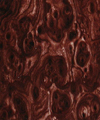

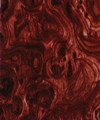

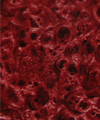

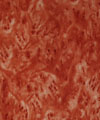

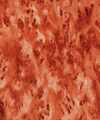

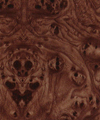

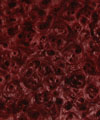

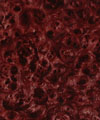

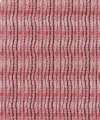

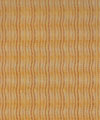

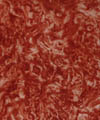

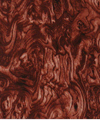

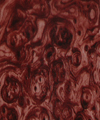

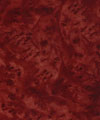

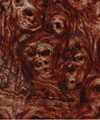

Showcase of some of our wooden grains

|

|

|

|

|

| TA001-3 | TA001-4 | TA001 | TA002-1 | TA002 |

|

|

|

|

|

| TA003 | TA004-1 | TA004-2 | TA004-3 | TA004-5 |

|

|

|

|

|

| TA004-6 | TA004-7 | TA004-8 | TA004-9 | TA004 |

|

|

|

|

|

| TA004-6 | TA004-7 | TA004-8 | TA004-9 | TA004 |

|

|

|

|

|

| TA005-1 | TA005-3 | TA005-4 | TA005-5 | TA005-6 |

|

|

|

|

|

| TA006-1 | TA006-2 | TA006 | TA007-1 | TA007-2 |

|

|

|

|

|

| TA007-3 | TA007-5 | TA007-6 | TA007-7 | TA007-22 |

|

|

|

|

|

| TA007 | TA008-2 | TA008 | TA010-1 | TA010-2 |

|

|

|

|

|

| TA010-3 | TA010-5 | TA010 | TA011-1 | TA011 |

|

|

|

|

|

| TA012-1 | TA012 | TA013-1 | TA013-2 | TA013-3 |

|

|

|

|

|

| TA013 | TA014 | TA015-3 | TA016 | TA017-1 |

|

|

|

|

|

| TA017-2 | TA017-3 | TA017-4 | TA017-5 | TA017-7 |

|

|

|

|

|

| TA017-31 | TA017-41 | TA017 | TA018 | TQ6002 |

|

|

|

|

|

| TA020-1 | TA020-2 | TA020-3 | TA020 | TA021-1 |

|

|

|

|

|

| TA021-2 | TA021 | TA022-2 | TA022 | TA023 |

|

|

|

|

|

| TA024-1 | TA024-2 | TA024 | TA025-1 | TA025-2 |

|

|

|

|

|

| TA025-3 | TA025-4 | TA025 | TA026-1 | TA026 |

|

|

|

|

|

| TA027-1 | TA027-2 | TA027-4 | TA027 | TA028-2 |

|

|

|

|

|

| TA028-3 | TA028-4 | TA028-9 | TA028 | TA029-1 |

|

|

|

|

|

| TA029-2 | TA029-3 | TA029-4 | TA029 | TA030-1 |

|

|

|

|

|

| TA030-2 | TA030 | TA031-1 | TA031-2 | TA031 |

|

|

|

|

|

| TA032 | TA034 | TA035 | TA036-1 | TA036-2 |

|

|

|

|

|

| TA036 | TA037-1 | TA037-2 | TA037-3 | TA037-4 |

|

|

|

|

|

| TA037-5 | TA037-6 | TA037-11 | TA037 | TA038 |

|

|

|

|

|

| TA039-1 | TA039-2 | TA039 | TA040 | TA041-1 |

|

|

|

|

|

| TA041-3 | TA041-4 | TA042-1 | TA042 | TA043-2 |

|

|

|

|

|

| TA043-3 | TA043 | TA045-1 | TA045 | TA046-1 |

|

|

|

|

|

| TA046 | TA047 | TA048 | TA049-1 | TA049-2 |

|

|

|

|

|

| TA049 | TA050-1 | TA050-3 | TA050-5 | TA050 |

|

|

|

|

|

| TA052 | TA053 | TA055 | TA058 | TQ6003 |

|

|

|

|

|

| TA061-1 | TA061 | TA062 | TA063-1 | TA063 |

|

|

|

|

|

| TA064 | TA065-1 | TA065 | TA066 | TA067 |

|

|

|

|

|

| TA068-1 | TA068-2 | TA068-3 | TA068 | TA069-1 |

|

|

|

|

|

| TA069 | TA071-2 | TA071-3 | TA071-4 | TA071 |

|

|

|

|

|

| TA072-1 | TA072-6 | TA072 | TA073 | TA076-3 |

|

|

|

|

|

| TA076 | TA079 | TA082-1 | TA082 | TA083 |

|

|

|

|

|

| TA084-1 | TA084-2 | TA084 | TA085-1 | TA085 |

|

|

|

|

|

| TA086-1 | TA086 | TA087 | TA089 | TA090 |

|

|

|

|

|

| TA091 | TA093-1 | TA093 | TA096-1 | TA097 |

|

|

|

|

|

| TA098 | TA099 | TA101 | TA102-2 | TA102-3 |

|

|

|

|

|

| TA102-5 | TA102 | TA103-1 | TA103 | TA104-1 |

|

|

|

|

|

| TA104 | TA108 | TA109 | TA110 | TA111 |

|

|

|

|

|

| TA112 | TA113 | TA114 | TA115-1 | TA115-2 |

|

|

|

|

|

| TA115 | TA116-1 | TA117 | TA118 | TA120 |

|

|

|

|

|

| TA121-1 | TA121 | TA122-4 | TA125 | TA131-1 |

|

|

|

|

|

| TA131-3 | TA131 | TA132 | TA133-2 | TA133-3 |

|

|

|

|

|

| TA133-4 | TA136 | TA137 | TA138-1 | TA140 |

|

|

|

|

|

| TA141 | TA142-1 | TA142 | TA144 | TA145-1 |

|

|

|

|

|

| TA145 | TA149 | TA152-2 | TA153 | TA154-1 |

|

|

|

|

|

| TA154 | TA155 | TA156-1 | TA156 | TA158 |

|

|

|

|

|

| TA159 | TA160 | TA161 | TA162 | TA165 |

|

|

|

|

|

| TA166-1 | TA166 | TA169 | TQ5501 | TQ5601 |

|

|

|

|

|

| TQ5701 | TQ5801 | TQ5802 | TQ5901 | TQ6001 |

IN-HOUSE OR OUT-SOURCE?

The decision to make transfers in-house or to out source them from UGI depends on your target market and your production requirements. If you plan to do small runs of special designs it would be cost effective to set up an in-house system to generate paper. Large bulk jobs would be best served by purchasing sublimation paper or other transfers from UGI.

Call us today on + (86) 135 333 11702 or email us [email protected]...and we'll gladly guarantee that you will receive the best product with great satisfaction at a best price!